1992-96 Audi S4/S6 Ignition System

Details and Troubleshooting Ignition Misfire on 1992-96 S4 AAN engine with coil over ignition?

The common misfire problems under load when the boost is increasing are usually caused by either a problem with the spark plug(s), one or more of the ignition coil connector leads, or from one or more defective ignition coil(s).

In less often cases, the Power Output Stage can also cause an intermittent misfire under load, so don't rule it out.

I also recommend checking and/or replacing your fuel filter, as a plugged filter can often feel like an engine misfire under high boost levels.

Ignition misfires that happen all the time are most often caused by a defective Power Output Stage (POS) that has one or more defective drivers used for a particular cylinder. Swapping the two POS units can sometimes locate the defective POS if the location of the misfire changes after the swap.

Keep in mind that it is also possible for the Power Output Stage (POS) to have an intermittent failure for one or more cylinders that only happens during driving which can make it difficult to locate by the swap method.

This may only happen when the POS gets warm/hot during normal operation or under extreme cold conditions.

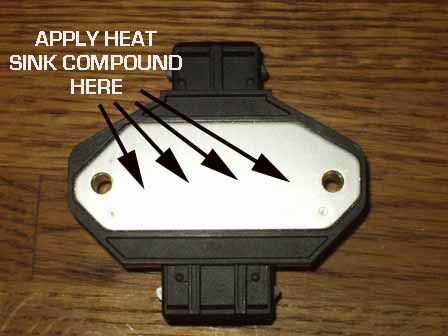

Poor heat sink conduction from the back of the POS to the metal bracket may cause thermal shutdown problems when the POS gets warm/hot.

The S4/S6's that are running higher boost levels seem to be more prone to ignition system problems as they are trying to provide a spark under very high cylinder pressures.

Trouble-shooting these ignition misfires can be tough as the problem may only occur under load and/or high boost conditions.

It can be difficult to locate which cylinder spark plug, coil connector lead, ignition coil or the particular intermittent POS that is causing the misfire problem under load.

One suggested method is to remove one fuel injector connector at a time and see if the misfire behavior changes when driven under load.

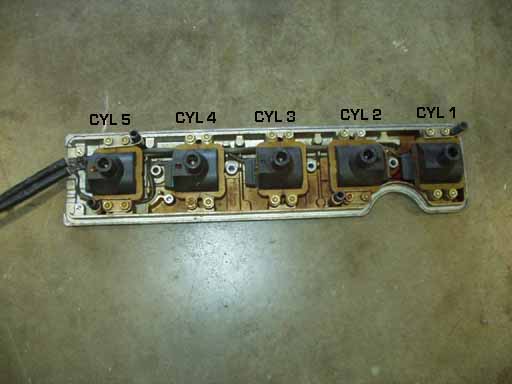

The Ignition coils are mounted individually in the top section of the valve cover.

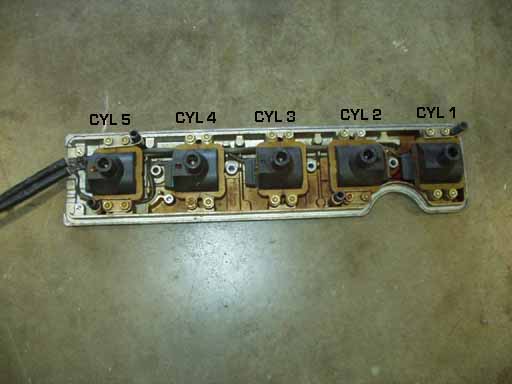

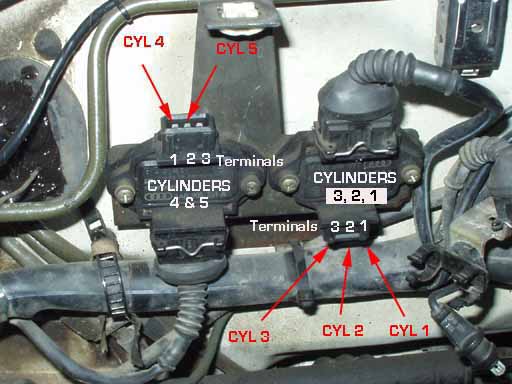

The System use two ignition coil Power Output Stages (POS). The Engine Control Unit (ECU) sends 5 separate control signals (one for each cylinder) to these 2 Power Output Stages which are used to supply the higher current needed to accurately turn on and then off the Ignition Coil to produce the high voltage ignition spark.

The Left POS is used for Cylinders 4 and 5, the Right POS is used for Cylinders

3, 2 and 1

Ignition Coil Power Output

Stages (POS)

Ignition Coil Power Output

Stages (POS)

If the misfire is happening all the time, even at idle, consider yourself lucky. You can remove the fuel injector electrical connectors one at a time with the engine idling and see if one cylinder has no change in idle speed or idle quality when the fuel injector is unplugged.

If you locate a misfiring cylinder this way, you can then swap the two Power Output Stages and see if the misfiring cylinder location changes which will tell you that one of the POS units is causing the problem.

The modules have Phillips screws with a nut on the back, holding them to the bracket on the firewall. The entire bracket with the two POS can also be removed, by removing the two 10mm nuts inside the plenum area under the plastic cover.

You may want to get some Heat Sink compound from your local electronics

supply store to apply to the back of the POS module to increase the heat transfer

between the POS and the metal bracket for improved cooling.

After swapping the two POS's, restart the engine and remove the fuel injector connectors one at a time to locate which cylinder is now missing.

If the misfire goes away completely,

then you most likely had a misfire on cylinder #3 in the original Right side POS, and now the unused channel (Terminal 3) from the Left POS is being used to drive Cylinder #3 with the Left POS being moved to the Right POS position.

If the misfire moves to another cylinder by 3 locations.

If the misfire moves from Cylinder 5 to 2, then the Left Side POS driver for Cylinder 5 was defective.

If the misfire moves from Cylinder 4 to 1, the Left Side POS driver for Cylinder 4 was defective.

If the misfire moves from Cylinder 2 to 5, then the Right Side POS for Cylinder 2 was defective.

If the misfire moves from Cylinder 1 to 4, then the Right Side POS driver for Cylinder 1 was defective.

If the misfire moved to cylinders 3, 2, or 1, then you should return the modules to their original positions and this indicates the left POS was the defective one and you may be able to rewire the input and output connections to utilize the one unused channel in this left POS.

If the misfire moved to cylinders 4 or 5, then your right POS was defective

and you may be able to rewire the two connectors on the Left POS to utilize

the one unused coil driver on Terminal 3 from the original Right side POS.

This is the lower connector on the Left Side POS.

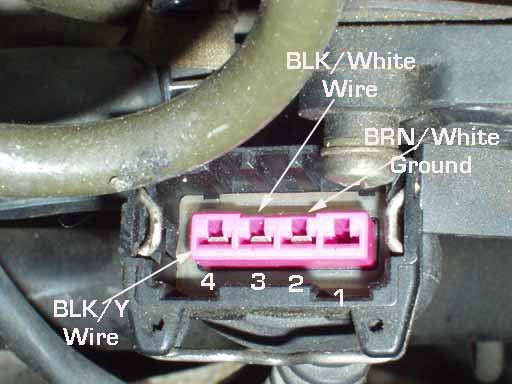

The BLK/Y wire should be for Cylinder 4

The BLK/White wire should be for driving Cylinder 5.

The BRN/White stripe wire is the ground for the POS.

Depending on which channel is defective, either one of these wire terminals can be inserted into the blank terminal opening after disassembling the connector housing to utilize the 3rd channel that wasn't being used previously.

The upper Connector on the POS that goes to the Cylinder 4 and 5 Ignition Coils also needs to have the appropriate terminal for cylinder 4 or 5 moved into the unused terminal location depending on which cylinder is being moved to the unused 3rd channel.

After the offending POS channel is identified you will end up with one 3-channel POS and one 2-channel POS. The 3- channel one goes on the right (looking at the firewall) for cylinders 1, 2, & 3, with the top & bottom harnesses plugged in normally. The 2-channel one goes on the left for cylinders 4 & 5. Swap the wires/terminals (if necessary) in the top & bottom harnesses for the left one to make sure the good 2 channels are now used; the dead one will be blank.

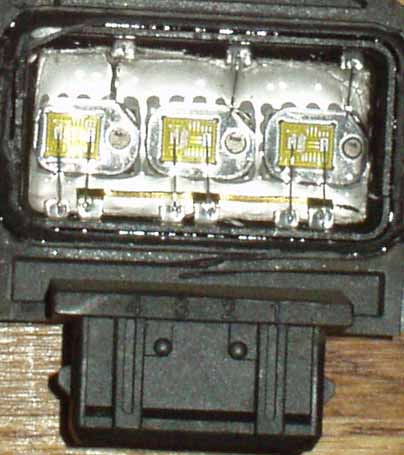

Looking Inside the POS

Ignition Coil Connector Lead

This system uses a ignition coil connector lead between the ignition coil and the spark plug which normally should have approximately 5000 ohm resistance when measured across each end with an Digital Multi-Meter (DMM) in the Ohms setting.

Unfortunately, this resistance test will only help locate a lead with excessively high or low resistance, and won't find the ones that are arcing across the rubber boot to the cylinder head under high loads due to deterioration and breakdown of the rubber boot.

One suggested method is to remove one fuel injector connector at a time and see if the misfire behavior changes when driven under load.

You can also swap in a complete set of 5 coil packs from another S4/S6. You can also install one new coil connector lead at each cylinder location, one at a time, and then test drive the vehicle after each swap, to try and locate which cylinder coil lead is causing the problem.

The Bentley manual also has describes a test where you remove the 5 spark plugs and lay the coil pack holder on its side with the spark plugs inserted into the coil leads. You lay the coil pack so that the spark plugs are grounded to the engine valve cover, and then have someone crank over the engine to watch for any weak or missing sparks.

This isn't a great test or conclusive for intermittent misfire problems, but for engines that are misfiring all the time, it may help locate which cylinder is having a problem.

MAKE SURE THE SPARK PLUGS ARE GROUNDED AGAINST THE METAL ENGINE VALVE COVER WHEN DOING THIS TEST!

If you remove the existing spark plugs and use them for this test, I recommend that you disconnect all of the fuel injectors electrically if you do this ignition test, as the cylinders can spray out fuel vapor that may ignite during this test.

Some autoparts stores sell a special coil testing spark plug which has the

center electrode missing or the type which has an adjustable spark gap which

can be used to test the output of the ignition coils.

The wider gap forces the ignition coil to output its maximum voltage and will

often stress it to locate a weak ignition coil.

If you suspect that you may have an defective ignition coil that only fails under high boost conditions, but are not sure, you may want to find a repair shop which has a portable exhaust analyzer. If you drive the car and monitor the exhaust gas levels, you will normally see a very high Hydrocarbon (HC) reading when the ignition system is failing and you have a misfire. Normally the HC reading will only be 50-150 ppm under load and high boost. With a misfire this reading will skyrocket often to over 1000ppm HC.

You may have to swap in a known good ignition coil into each coil position one at a time and then test drive the car under load/boost until you locate the defective coil.

Ignition Coil Testing Information

I worked on one 1994 S4 recently with a misfire that only occurred when the boost level was above ~1.6 bar when the ignition system is under the most strain. I first tried checking the coil connector lead resistance, then tried replacing the 5 spark plugs, then I tried connecting a known good used ignition module in place for the module for cylinders 1, 2, but the misfire was still there.

Then I changed the module for cylinders 3, 4 and 5 with the used good module. This did not affect the misfire either, so I pulled the coil pack from the top of the engine and disconnected the connectors at the firewall. I installed a known good coil pack from another S4 and found that the intermittent misfire was gone.

Then I went back to the suspect coil pack and tested each of the 5 short ignition wire connectors to make sure they each had approximately 5k ohms of resistance. Each of the 5 ignition coil wire connector leads tested ok.

Then on the suspect coil pack I tested the resistance from the center of the coil high voltage output to the metal case of the coil.

NOTE: This conductance and resistance test is not 100% effective in locating which coil is defective in every misfire case, but when the defective ignition coil has an open circuit with very high resistance, it may help locate the problem coil.

One other suggested method is to remove one fuel injector connector at a time and see if the misfire behavior changes when driven under load.

When using a Fluke 87 DMM set to the 40 Mega-ohm resistance test range, and with the Positive lead connected to the center coil output and the DMM common lead connected to the coil metal case, I saw very very high resistance readings.

The DMM showed "OL" which means the measurement is over 40 Mega-ohms and is too large to correctly display or measure correctly. One of the ignition coils looked to have been replaced recently on Cylinder #4 which may explain why it measured only 5.4 Mega-ohms, when all of the other cylinders ignition coils measured over 40Mega-ohms, and gave the OL reading on the DMM.

The Fluke 87 DMM has a unique range

when measuring very high resistance, up to 100,000 Mega-ohms, it is called the

conductance range that reads in Nano-Siemens (nS). One Nano-Siemen is 1 X10-9

Siemens, or 0.000000001 Siemens.

The DMM range for this setting is 40nS.

You can convert a conductance measurement in Siemans to its equivalent resistance

in ohms, by dividing 1 by the Siemens reading.

For example: 2.00 nano-Siemens equals

500,000,000 Ohms resistance (500 Mega-Ohms)

Calculation: 1/(2.0X10-9)

I measured across the ignition coil center output using the Fluke 87 DMM in the regular Mega-ohm resistance range and using the special Conductance range setting with the common test lead on the coil metal case, and the positive test lead on the coil High Voltage output center conductor.

| AAN Engine | Resistance in Ohms | Conductance in nano-Siemens (nS) |

| Cylinder 5 | OL (above 40.0M) | 16.5nS |

| Cylinder 4 | 5.4 M | OL (above 40.0nS) |

| Cylinder 3 | OL | 23.85nS |

| Cylinder 2 | OL | 0.02nS |

| Cylinder 1 | OL | 16.80nS |

Notice that cylinder #2 ignition coil has a very low conductance reading 0.02 nS, which equates to a very high resistance reading, almost up to 100,000 Mega-Ohms which is near the limit of the DMM.

I suspected that this Cylinder #2 coil was the one causing the intermittent misfire. Replacing coil #2 fixed the problem, my assumption was correct!

The known good S4 coil pack I used for test purposes had the following readings when I measured across the ignition coil center output using the Fluke 87 DMM in the Mega-ohm resistance range and also when in the special Conductance range setting with the common test lead on the coil metal case, and the positive test lead on the coil High Voltage output center conductor.

| AAN Engine | Resistance in Ohms | Conductance in nano-Siemens (nS) |

| Cylinder 5 | 5.05M | OL (above 40nS) |

| Cylinder 4 | 3.84M | OL (above 40nS) |

| Cylinder 3 | 6.60M | OL (above 40nS) |

| Cylinder 2 | 6.07M | OL (above 40nS) |

| Cylinder 1 | 6.30M | OL (above 40nS) |

Copyright © SJM Autotechnik™ , all rights reserved

Return to Troubleshooting Tips page.

Return to SJM Autotechnik™ main page.