ECU Fault Code Retrieval,

ECU Output Tests

1987-88 5000S and 1989-91 Audi 100 with NF engine and CIS-E-III

Introduction:

Engine Control Unit (ECU) Fault Code System The 1987-88 5000S and 1989-91

Audi 2.3 liter 5 cylinder naturally aspirated engine (NF engine code)

with CIS-E-III fuel injection have a separate Fuel Injection Control

Unit and a separate Ignition control unit which are equipped with a

"self-diagnostic system"[2]. This system can test 14 input and 4 output

system checks.

Anytime an engine problem is occurring, this Fault Code system should

be used to first locate any system fault codes that have been recorded.

If the vehicle starts:You should drive the car for a minimum of 5-10

minutes and raise the engine speed above 3000 RPM and ensure that the

throttle is opened fully during the test drive. You want the engine

coolant temp to get above 80C, (176F).

If the vehicle does not start: Crank the engine with the starter for

at least 5 seconds. NOTE: The ignition should NOT be turned off after

doing this full throttle test road test or after the "No Start" cranking

test is done, as the fault memory may be erased. After doing the road

test or the "No Start" cranking test, proceed to the section below for

reading any fault codes stored during this process. The Check Engine

Warning light, should come on with the ignition key on if the bulb is

installed and functioning.

In some cases, people accidently remove a fuse they think is

a "SPARE" fuse in the fuse box but they end up disabling fuel or igntion

control systems on their engine.

The following fuses should be checked first.

(Fuse 13 for Fuel Pump),

(Fuse 21 supplies +12V to the black fault code connector and to the

Fuel Injection Control Unit (FICU) memory),

(Fuse #26 is for Check engine light bulb),

(Fuse #27 is for the Ignition Control Unit).

FUSE #28 is often mistaken as a SPARE fuse, it is not!

Fuse #28 is for the FICU and for the FICU controlled solenoids.

These all should be checked if the fault code system or the engine fuel

system does not operate as expected. 1987-88 5000S, check the wiring

diagram for details on which fuses are used for this system. The Black

fault code connector should have +12V on the top pin, and ground on

the bottom pin. Check engine and vehicle grounds if Fuel Injection or

Ignition Control units are suspected as being faulty.

Switch A/C system off during fault code retrieval. For the 1989-91 Audi

100, apparently there are two versions of the CIS-E-III fault code memory

system, one for 49 state vehicles, and one for California Vehicles with

slightly different emission control systems. The 49 State version has

Temporary Fault code storage which will be erased each time the ignition

is turned off. The 49 State version uses the 443-906-264C Fuel Injection

Control Unit and the 443-907-397C Ignition Control Unit.

The California version has permanent fault code memory which retains

the fault codes even after the ignition has been turned off [2].

(Note: Part numbers are for reference only, consult your local Dealer

parts department for the latest part number information.)

Fault Code Reading, 1987-88 5000S, 1989-91

100

The later 89 -91 Audi 100 uses two diagnostic connectors one black and

one brown, under the driver side dash.

The 1987-88 5000S and the early 1989 Audi 100 do not have these diagnostic

connectors installed. The fuse in the top of the fuel pump relay can

be inserted for 4 seconds to initiate the fault code sequence in the

early system without the diagnostic connectors under the dash.

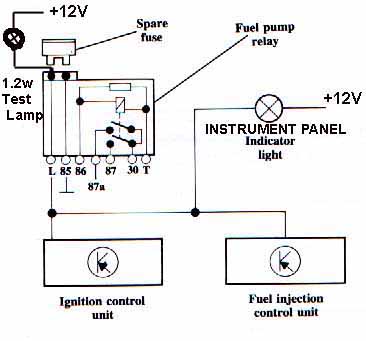

If you don't have the diagnostic connectors and you don't have the "Check

Engine" light bulb installed in the instrument cluster, you will need

to connect the test light to one of the Fuel Pump Relay contacts (Contact

"L") and connect the other end of the test lamp to +12V in order for

the ECU to blink this light so you can read out the fault codes.

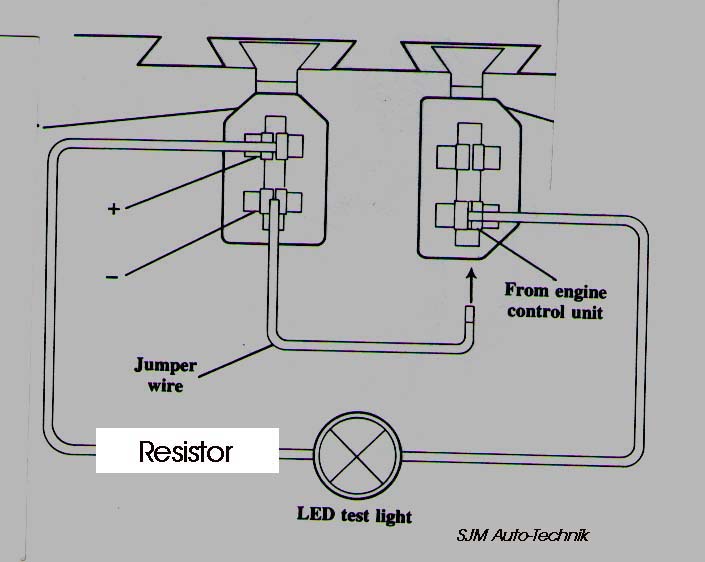

Here is a picture showing the connections between the fuel pump relay

and the two Engine control units and the connection of a test lamp to

one of the terminals in the top of the fuel pump relay, in order to

blink out the fault codes.

Diagram Courtesy of Audi of America

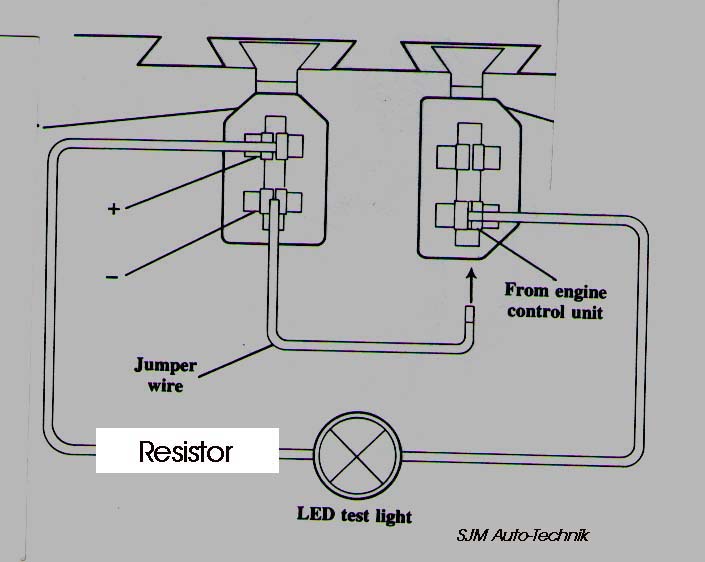

If you do not have the light bulb installed in the dash, but you DO

have the diagnostic connectors, you will need to connect an LED or low

wattage light bulb (12 volt, 1.2 Watt) across these color coded diagnostic

connectors in order to have the fault codes blinked out.

To initiate the fault code system in the late 1989 Audi 100 and 1990-91

Audi 100, a jumper wire and LED can also be inserted into the fault

code connectors under the dash instead of using the fuel pump relay

fuse insertion method.

Diagram courtesy of Audi of America

IMPORTANT DETAILS: This yellow "Check" engine light will normally come

on when the ignition is turned on "if" the bulb is installed in the

dash. The operators manual refers to this "Check" engine light as the

"Emission Control System (ECS)

malfunction Indicator Light."

Diagram courtesy of Audi of America

Some of the Audi 100's have no "check engine" light bulb installed in

the dashboard assembly even though the circuitry is there. Normally

this bulb is installed in-between the "Airbag" light and the "Door Open"

warning light on the right side of the dash and this light should come

on when the ignition key is first turned on.

If you do not have the light bulb installed in the dash, you will need

to connect an LED or low wattage light bulb (12 volt, 1.2 Watt) across

these diagnostic connectors in order for the ECU to blink this light

so you can read out the fault codes. Vehicles produced for sale in California

should have this "Check Engine" light bulb installed in the dash. The

documentation for the late 1989 Audi 100 and the 1990-91 Audi 100 shows

a black and brown connector, but no blue connector.

Connect the LED positive terminal (LED's are polarity sensitive) to

the top black terminal, and the negative LED terminal to the bottom

terminal in the brown connector as shown. Use a jumper wire between

the bottom black connector terminal and the same bottom terminal in

the brown connector to short for 4 seconds then remove jumper, to initiate

the fault codes (ignition key on, with or without the engine running).

Check the Bentley Manual for additional information.

BLINKING OUT THE FAULT CODES

As mentioned, with the ignition on or with the engine idling, you activate

the fault code system by inserting the fuse in the top of the fuel pump

relay for four seconds OR by connecting the jumper wire across the two

diagnostic terminals under the dash for four seconds, after removing the

fuse or jumper, the diagnostic system will then begin the sequence to

blink out the fault codes via the instrument panel "Check" Engine light

or by flashing the LED connected across the diagnostic connectors. Each

fault code consists of four groups of pulses. The sequence for displaying

the fault codes is a start sequence of 2.5 seconds with the lamp on, and

2.5 seconds pause with it off.

Then the fault code output follows as a half-second pulse with the LED

light on, separated by a half-second pause with the LED light off, with

a larger pause of 2.5 seconds between each set of pulses. Example:If no

fault codes are stored, code 4444 will be displayed by the Control unit

flashing the LED.

The control units will flash the LED on and off as follows after the jumper

wire is inserted into the connectors for 4 seconds and then removed. LED

on (2.5 sec), LED off (2.5 sec) Now here comes the code 4444 Blink, pause,

Blink, pause, Blink, pause, Blink, (2.5 second pause) Blink, pause, Blink,

pause, Blink, pause, Blink, (2.5 second pause) Blink, pause, Blink, pause,

Blink, pause, Blink, (2.5 second pause) Blink, pause, Blink, pause, Blink,

pause, Blink, (2.5 second pause)

For example: Code 2322 (Air Temperature sensor) would be displayed as

follows:

The sequence of displayed pulses will repeat until the system is stepped

to the next fault code stored (if any) by connecting the jumper wire across

the connectors again for 4 seconds. The LED will blink once at 2.5 second

intervals to indicate that the last error code has been read. Use a note

pad to write down the fault codes as they are displayed and then check

for the specific fault code description listed in the section below. Check

the Bentley Manual for additional information.

In my 1989 200TQ, I have permanently connected a momentary push button

switch across the two jumper wire connections so that I only need to push

this button to activate the fault codes. I ended up installing the "check"

engine light bulb back in the dash to avoid having to use the LED connected

under the dash.

Permanent Fault Code Memory Erasing, 1989-91

Audi 100 with CIS-E-III (California Vehicles Only) On California vehicles,

the permanent fault code memory can be erased by stepping through the

Output test below, then after the 4 output tests have been completed,

the check engine light/LED should blink on for 2.5 seconds, then off for

2.5 seconds. Now, Insert the fuse or jumper again for 10 Seconds, then

remove the fuse/jumper and the fault code light should stay on continuously,

indicating the fault code memory has been erased. This may also be possible

on the 1987-88 5000S, but I have not verified this.

Output Tests 1987-88 5000S, and 1989-91

Audi 100 with CIS-E-III There is also an "output test" mode that will

enable the Control unit to energize the CIS differential pressure regulator

and cycle the electrical solenoids on and off to verify they are working

correctly.

The full throttle switch must be working correctly to initiate these output

tests. To activate the Output Tests, you must first insert the fuse into

the fuel pump relay, or connect the LED and the jumper wire to short across

the Fault Code Connectors as shown and THEN turn on the ignition to start

the output tests. Remove the fuse or jumper wire after 4 seconds:

- (Test #1) The code 4341,will be displayed by the fault code light/LED.

The Differential Pressure Regulator with have 10 milli amps applied

to this regulator when the full throttle switch is manually closed.

100 milli amps when the throttle switch is open

- Insert the fuse, or connect the jumper wire again for 4 seconds

to go to the next output test:

- (Test #5) Code 4343, Close the full throttle switch again, and the

Carbon Canister Solenoid valve is cycled on and off.

- Insert the fuse, or connect the jumper wire again for 4 seconds

to go to the next output test:

- (Test #2) Code 4431, will be displayed. Close the full throttle

switch and the Idle Stabilizer valve cycles.

- Insert the fuse, or connect the jumper wire again for 4 seconds

to go to the next output test:

- (Test #4) Code 4443, Close the full throttle switch and the Cold

Start Valve will be cycled on and off for 10 seconds,

- (Test #7) Code 0000, End of Output Test Procedure (Light on for

2.5 seconds, then off for 2.5 seconds indicates code 0000)

- Again, check the Bentley Manual for more details.

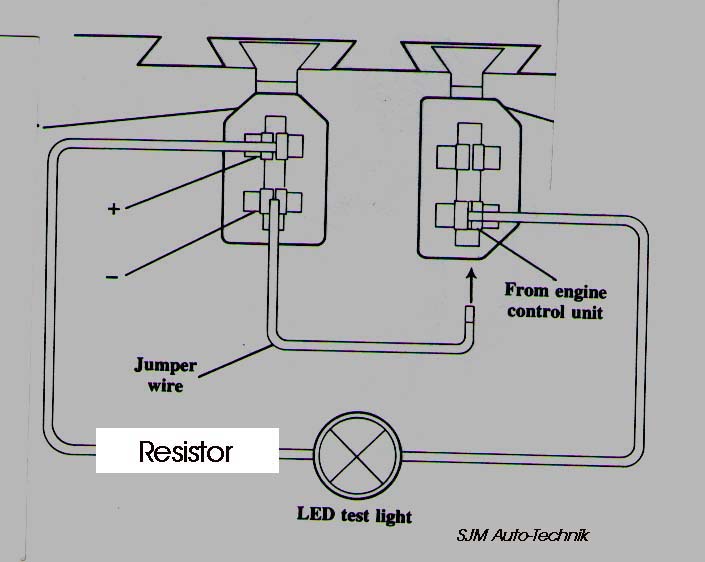

LED "Test Light" Construction, for blinking

out fault codes. (1989-91 100) The LED with a series resistor is normally

connected across two terminals on the fault code connectors. The LED normally

needs a resistor in series to limit the current, most LED's operate with

10-30 milli-amps (0.010 to 0.030 amps).

A 1/4 watt 680 ohm resistor works pretty well but you don't have to use

a resistor with exactly 680 ohms. The current that is flowing through

the LED test light circuit is calculated as follows: Charging system voltage

minus voltage drop across LED, divided by the resistance (14 Volts - 1.2

Volts)/680 = 18.8 milli-amps (0.0188 amps).

The lower the value of resistance, the more current that flows and the

brighter the LED, up until the point the smoke gets out. Radio Shack should

have the necessary components to build this LED test light. There are

some newer "Super bright" LED's that some electronic supply houses carry

that should work great in this application. Here is a diagram that illustrates

the connection of the resistor in series with the LED.

Diagram courtesy of Audi of America

I normally use two different colored. wires (black/red) as the LED is

polarity sensitive, the flat section on the LED lamp is normally the negative

connection. Bolt lug terminals (U shaped) with one leg trimmed off, can

be crimped on the wire ends to allow easy insertion into the fault code

connector terminals.

It won't hurt it if you connect the LED backwards, it just won't make

any light.....the resistor can be connected in series on either the +

or - wire to the LED.

Fault Code Listing [2] [3]

NOTE: The fault codes shown below indicate that the Control unit has recorded

a problem with one or more of the following: A system component, the wiring,

the wiring connections, or from a engine mechanical problem (vacuum leak,

low compression, etc.). If you get multiple fault codes recorded, step

through the fault code reading sequence and write down all the fault codes

that were recorded.

After you locate the source of the problem for the "first" fault code

you read, you may want to then clear all the fault codes stored and drive

the car again to see if the other fault codes are stored again. In some

cases multiple fault codes are recorded even though there may be only

one problem with the system. Code Number Source of Fault code Possible

cause Recommended Check or Repair Symptom in some cases

- 1111 Fuel Injection Control Unit (FICU) or Ignition control unit

(ICU) Defective Check vehicle electrical system grounds, Replace control

unit if no wiring or +12V supply faults found

- 1231 (1989-91 Audi 100 only) Transmission speed sender (G68), Signal

used by Ignition Control Unit (ICU), check sensor output. Disconnected

wire between instrument cluster and Fuel Injection Control Unit. Check

instrument cluster internal circuit board connection pin solder joints.

Instrument cluster repair

- 2121 Idle switch Switch open ckt, stuck closed Switch defective,

mechanical linkage problem, or wiring problem

Also check speedometer speed sensor in transmission, and wiring from

sensor to speedometer in instrument cluster. Faulty speedometer signal

can cause stalling. Poor solder connections in the instrument cluster

is usually the cause.

- 2122 Engine speed sensor signal missing. Signal used by Ignition

Control Unit, Hall sender (G40) faulty, Disconnection between terminal

17 of Ignition Control unit (J154) and terminal 30 of Fuel Injection

Unit (J21). No RPM signal from Ignition Control Unit (J154) to Fuel

Injection control unit via knock control. Ignition Control Unit (J154)

or related wiring defective.

- 2123 Full load/full Throttle switch Switch open ckt, stuck closed

Switch defective, mechanical linkage problem or wiring problem

- 2132 1989-91 Audi 100 Only Data Wiring Defective, check wiring (California

Vehicles only)

- 2141 Knock regulator Regulator limit exceeded, Excessive knock,

timing is being retarded by maximum amount, Fuel octane too low, Excessive

Compression, carbon build up in combustion chamber

- 2142 Knock sensor Open or short circuit, Defective sensor Check

sensor and wiring Symptom: Timing retarded, High fuel consumption,

power loss,

- 2223 Altitude Sensor defective, check sensor output and wiring

- 2232 Air Flow Meter plate rotary Potentiometer (resistive Sensor)

defective, check sensor output and system wiring

- 2233 Air Flow Sensor (G70) Reference voltage, Disconnection between

terminal 26 of Fuel Injection control unit (J21), and terminal 21

of Ignition control unit (J154)

NOTE: The reference voltage for load and altitude signals is monitored

by the CIS-E-III Fuel Injection control unit and NOT as indicated

on the VAG 1551/1552 diagnostic tester. The reference voltage is from

the Air flow sensor potentiometer. NF engines do not have an Air Mass

Sensor, they use a Potentiometer on the air flow meter assembly below

the fuel distributor..

- 2312 Coolant sensor Open or short circuit, Defective sensor or wiring

Symptom: Cold starting difficulties at low temperatures, Poor idle

and acceleration during warm up

- 2341 Oxygen Sensor Control Regulating Limit exceeded

- 2411 1989-91 Audi 100 only Exhaust Gas Recirculation Valve, (California

Vehicles only)

- 4431 Idle Stabilizer Valve (ISV), Signal used by Ignition Control

Unit

- 4444 No Faults have been recorded.

- 0000 End of Diagnostic Output, code 0000 is signaled by the Check

Engine or LED light coming on for 2.5 seconds, and then being off

for 2.5 seconds

References: [2] Audi 100, 200 Official Factory Repair Manual Volume

1, Robert Bentley Corporation

References: [3] Audi of America, Technical service training publications:

"1986 Model Change Information-publication

"1989 Model Change Informaton-publication All rights reserved.

"2.3 Liter Engine with CIS-E III Engine Control System"

(Dec./1986)

Copyright © SJM Autotechnik™ , all rights reserved

Return to Troubleshooting Tips page.

Return to SJM Autotechnik™ main

page.