ECU System,

1986-90 5000/200TQ:

Oxygen (O2) Sensor, Open Loop and Closed Loop Operation

Testing the O2 Sensor

Testing O2 with DMM

Testing O2 with Oscilloscope

Sensor Problems

Basic Operation Details:

The oxygen sensor is mounted in the exhaust pipe just after the turbo

exit.

The O2 sensor has a internal heating element to ensure quick warm up

and correct operation at idle. There are three wires going into the

O2 sensor on the Audi Turbos. One ground, one +12V signal, and one for

the actual O2 sensor output voltage.

If you have trouble with the O2 sensor working correctly at idle, the

heating element inside the sensor may be defective. The fuel pump relay

supplies +12V to this sensor and to other engine solenoids through circuit

87a, you should check for +12V and ground across the two terminal connector

to the O2 sensor with the engine running.

You can also check the heater inside the O2 sensor by disconnecting

the two terminal connector for the O2 sensor heating circuit, and then

measure the resistance across the O2 sensor heating element, it should

read around 5 ohms, but this resistance will vary a little as the sensor

warms up. The resistance will read open circuit (infinity ohms) if the

element is burned out.

The sensor heating element draws 1.7 amps when first energized, the

current will drop to around 1.0 amps after the heating element gets

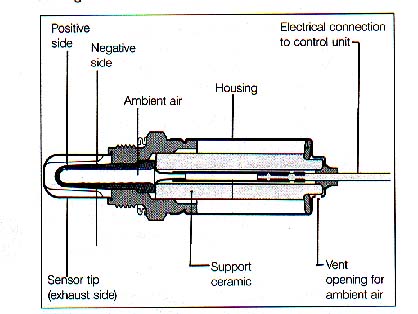

warm. The O2 sensor incorporates a vent to outside ambient air for a

reference to compare to the oxygen level in the exhaust gas.

This vent is normally in the area where the wires exit the sensor, so

be careful not to get water or other debris in the top of the O2 sensor

when cleaning the engine. Here is a picture of the O2 sensor with it

removed from the exhaust down pipe.

When the engine is first started when it is cold, the engine will briefly

run for 1 or 2 minutes in open loop operation based on the "basic" idle

mixture setting in the CIS Fuel Distributor/Air Flow Meter assembly

and by the duty cycle programmed into the ECU.

Normally the basic idle mixture is set to be 0.6% to 1.2% Carbon Monoxide

(CO) when the exhaust gas is measured up stream of the catalytic converter.

Once the Oxygen (O2) Sensor warms up (Heated O2 sensor), the system

will switch over to closed loop operation.

This sensor is used to monitor oxygen levels in the exhaust and acts

as a voltage supply that transitions high to low when the oxygen level

is high (slightly lean above 14:7 to 1 air fuel ratio) and transitions

low to high when the Oxygen level is low (slightly rich air fuel mixture

below 14:7 to 1 air fuel ratio).

The ECU uses this oxygen sensor signal to tweak the air fuel mixture

back and forth close to the ideal 14.7 to 1 Air Fuel Ratio. With the

fuel system in closed loop operation after the O2 sensor warms up, the

O2 sensor voltage cycles up and down between ~0.1V and ~0.9V.

At idle, the O2 voltage should cycle back and forth 1 to 2 times per

second and when cruising, it should cycle back and forth ~4 to 5 times

per second. This cycling occurs because the engine computer senses the

O2 voltage and then changes the duty cycle going to the CIS Frequency

valve (Mixture solenoid).

This Frequency valve alters the lower chamber pressure in the fuel distributor

which alters the fuel flow out to the injector. This switching action

allows the ECU to do minor adjustments to the air fuel ratio to allow

the catalytic converter to perform its job to optimize the "oxidation"

of Carbon Monoxide (CO) and Hydrocarbons (HC) and the reduction of Nitrogen

Oxides (NOx).

The oxidation occurs when the mixture is slightly lean and more oxygen

is available, and the reduction occurs when the mixture is slightly

rich and less oxygen is available. These chemical reactions that occur

in the catalytic converter ensure the lowest possible emissions out

the tailpipe. Catalytic converters typically operate at 60-90% efficiency

depending on age.

This means that the amount of exhaust emissions that enter the catalytic

converter are reduced approximately by this percentage. For example,

in the Audi I5 turbo engine, at idle, you typically have exhaust gas

entering the catalytic converter with a Carbon Monoxide (CO) level of

1.2%, this will be reduced to ~ 0.36% to as measured at the tailpipe

with a 70% efficient converter.

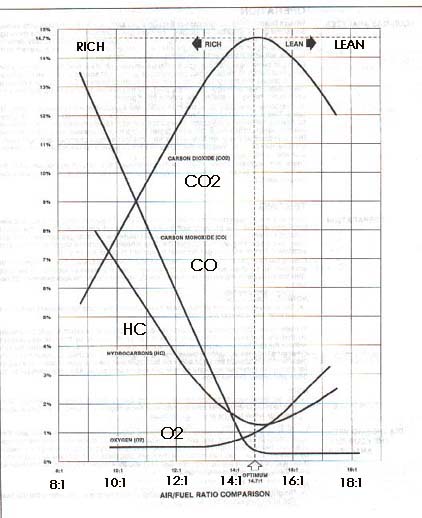

Here is a chart showing the relationship between the various exhaust

gases and air/fuel ratios.

Diagram courtesy of MPSI Emission Control Training Manual

You can watch the Frequency valve duty cycle change back and forth on

an oscilloscope screen and if you connect up the O2 voltage signal on

channel 2 and the frequency valve signal on channel 1 of the o-scope.

You will see how the high (rich) O2 voltage will cause the frequency

valve duty cycle to be reduced in order to lean out the mixture.

NOTE: If the Oxygen sensor or wiring fails, the ECU will use a 50% duty

cycle to operate the frequency valve.

O2 SENSOR - TESTING

If the O2 sensor wire is disconnected with the engine running, the ECU

normally has a 0.450 V (+/- 0.050V) reference voltage on the ECU wire

connecting to the O2 sensor.

The ECU will switch over to a basic idle mixture setting (frequency valve

duty cycle set to 50%) with the O2 sensor disconnected. If you suspect

the O2 sensor is causing a running/drive-ability problem, you can temporarily

disconnect the sensor and drive the car to see if the problem still exists.

The system is designed to operate without the O2 sensor connected and

the engine will run fine assuming the other systems/components are functioning

properly and the basic idle mixture is set correctly (upstream idle mixture

CO% is set between 0.6% to 1.2%).

Please note that disconnecting the O2 sensor will store a fault code in

the ECU. The ECU O2 signal wire is the large green wire with male and

female spade connector under the small rubber boot.

The 1986-88 5000 Turbo and 5000 Turbo Quattros have this O2 sensor green

wire and rubber boot over the connector laying along the right fender

lip and the fuel distributor/air flow meter assembly. The later 89-90

200T/Q with the dual knock sensor MC engine have this rubber boot connection

on the back engine firewall area on the bracket with the other color coded

connectors.

DMM TESTING

You can also use a Digital Multimeter (DMM) to do a basic test of the

O2 sensor voltage with the sensor connected to the ECU, but the meter

normally will not respond quickly enough to see the voltage go up and

down. It is important to know what the input impedance is of the meter

you are connecting across the O2 sensor or for that matter across any

of the ECU inputs/outputs.

Most modern DMM's have a 10 Mega-ohm input impedance. Many of the older

analog meters have a input impedance down below 100K ohms. These older

meters "may" work once your O2 sensor is warmed up as the impedance of

the O2 sensor usually drops to 5-20k ohms.

If your DMM has a "analog" type bar graph feature, you can measure the

O2 voltage and see changes, as this bar graph display responds quicker

and this can be used to monitor the O2 sensor voltage as it swings high

and low when the ECU/fuel system is in closed loop operation. If the DMM

has a "zero" feature to zero out the bar graph reading with a voltage

applied, you can connect the DMM to the O2 sensor wire and turn on the

ignition before starting the warm engine.

The DMM should read ~0.45V with the meter connected to the O2 sensor wire

with the ignition on, but with the engine not running. Now zero out the

0.45V reading, and start the engine. The DMM bar graph should oscillate

up and down around this 0.45V reference voltage 1 to 2 times per second,

indicating that the system is in closed loop operation.

OSCILLOSCOPE TESTING

One test you can do with the O2 sensor wire connected to the ECU, is to

use an oscilloscope to measure the O2 sensor voltage and then force the

mixture rich with the slow addition of propane into the intake system.

The O2 sensor voltage should rise up to at least 0.85 volts. Then force

the mixture lean by creating a huge vacuum leak and measure the O2 voltage

transition time when the voltage drops from high to low.

To quickly force the mixture lean, you can pull off a large hose from

the intake manifold, or remove the oil cap from the valve cover (10V Turbo

only). This will make the engine stall but you can capture the O2 voltage

response on the digital oscilloscope.

Typical transition times are around 25-50ms, the rule of thumb is that

the O2 sensor transition time from 0.6V to 0.3V or from 0.3 to 0.6V should

be under 100ms. The O2 sensor will have a different transition time going

from rich to lean than from lean to rich, if I remember correctly the

rich to lean transition is slightly longer.

It is important to understand that if the VAG1552, the DMM, or the Oscilloscope

shows the O2 sensor voltage stuck high or low and not oscillating up and

down, that the sensor may be working correctly. The real problem may be

mechanically related (lean condition from vacuum leak) or engine fuel

system may have a problem (rich mixture from fuel pressure being too high).

When the engine is running very lean (low O2 voltage) or is running very

rich (high voltage) the ECU can not tweak the mixture enough to compensate

for these problems. The O2 sensor heating element could also be defective,

and this can cause a cold O2 sensor at idle with no fluctuation in output

voltage. O2

SENSOR PROBLEMS

One problem that affects the O2 sensor operation is contamination or

poisoning by silicone, this shows up as a fine white powder on the tip

of the sensor and will reduce the voltage output of the sensor when

the mixture is rich, and this will cause a loss of fuel economy and

increased CO and HC emissions. You may also see a negative voltage developed

under lean operation when the sensor is poisoned by silicone. This poisoning

causes the sensor to see a lower proportion of Oxygen.

The slots in the tip of the O2 sensor can also get partially clogged

with carbon which will increase the response time. This will cause the

O2 voltage change to slow way down, taking 3-4 seconds to go up and

down, instead of changing in less than a second. This slow response

can cause a varying idle speed and varying idle mixture.

The exhaust gas Carbon Monoxide (CO) reading will not be steady at idle

when read by an exhaust analyzer. This can also cause some light surging

under light acceleration with the engine cold and when fully warmed

up under cruise conditions.

There are several Society of Automotive Engineers (SAE) articles that

have been published since the early 70's that describe in the utmost

detail the operation of these O2 sensors.

Here is a photo showing some details on the O2 sensor construction.

Diagram courtesy of Robert Bosch Corporation

Here is an excerpt from the 1976 SAE article #760287

"Closed Loop Control of Lean Fuel-Air Ratios using a temperature compensated

Zirconia Oxygen Sensor"

"The sensor is based on the electro-chemical potential developed across

a zirconium dioxide solid electrolyte when its two electrodes are exposed

to differing oxygen concentrations. One electrode is exposed to the

constant oxygen pressure of ambient air and the other to the oxygen

pressure of the exhaust gas which varies with equivalence ratio.

A voltage is produced which is a function of the equivalence ratio."

Most university libraries have the articles going many years back on

micro-fiche and they should have an index that lists all the articles

by subject, author and number.

Go to O2 Sensor and Emission Article

Listing for details.

Bosch Replacement 3 Wire Oxygen Sensor

Bosch makes a replacement 3 wire O2 sensor which is sold in large quantities

and carries a reasonable price. This generic O2 sensor can be used in

the Audis if you use your original wiring and connectors and splice

it to the wires on the new oxygen sensor.

Universal O2 sensor and O2 sensor with harness

I use the smaller gauge (red) butt type crimp connectors to splice

the original O2 sensor wiring to the new generic O2 sensor.

I cut the O2 sensor wires to have different lengths, so I can space

the crimp connectors in different locations to allow them to slide inside

the original wire sleeve to protect them from the elements.

Return to ECU System Technical Tips

Copyright © SJM Autotechnik™ , all rights reserved

Return to Troubleshooting Tips page.

Return to SJM Autotechnik™ main page.